Engine Tuning & Repair

|

|

We offer several torque and power kits for models from 1969 to 2000. Be it a valve drive kit or a cylinder set, we always keep suitability for everyday use in mind. Every engine type, a cafe racer or a sidecar bike, has its own needs for optimisation. In all cases, we have a carb setup to match. Either new measurements are made on our dyno, or we have this data from prior measurements. In this case, do it yourself installations is possible.

Engine/Gearbox Repair

|

|

First we take the engine/gearbox apart completely. Parts are cleaned and measured. The we make a cost estimate, including possibilities for tuning and optimisations. In most cases, we can use better parts, either from newer Moto Guzzi models or from our own production.

We also have possibilities to blast aluminium surfaces with stainless steel balls. This cleans and condenses the surface and makes it less sensitive for the future.

Tuning for models up to 2000

When it comes to tuning, our 2-valve engine kits have proven their quality for over a decade.

Our main aim, however, is not to get the last possible horsepower from an engine, but to create steadfast affordable engines and a logical concept catering for the different engine types. Feel free to see for yourself – we have a few tuned Guzzis here at all times for a demonstration. After all, a test drive is more convincing than figures and performance diagrams. Our setups are are done on our Dynojet dynamometer and on the road.

The following chart shows the suitability of the different engine types for tuning and the expected increase in PS/Nm. The values are guidelines only, as they depend on the condition of the engine and the tuning measure required. After working out the tuning measures needed, the carburettor balancing will be done individually, either according to values that we gathered from similarly set up machines or according to a lambda test ride with a test device developed by us.

| V7-Sport 750-S,S3 V7-Spez. |

T3,T4,T5 Cali 2-3 Mille GT 1000 SP SP-2 |

LM 1, 2, 3 Cali 3, 2. Serie Mille GT, 2. Serie 1000 SP-3 1000-S 2. Series |

LM-1000, 1000-S 1. Series |

Cali. 1100-i |

1100-Sport Vergaser (with Oilcooler) |

1100-Sport-i V11-Sport |

|

| Camshaft Kit HMB K-7.7 |

+8/+8 | ||||||

| Camshaft Kit HMB D-8.1 |

+8/+8 (see *4) |

+9/+10 | +9/+10 | ||||

| Camshaft Kit HMB D-7.2 |

-2/+10 | ||||||

| Camshaft Kit HMB L-7.9 |

+10/+10 (see *1) |

+3/+5 | +3/+5 | ||||

|

Combustion Chamber Rework |

+4/+4 | +4/+4 | +4/+4 | +4/+4 | +4/+4 | +3/+5 | +3/+5 |

|

Twin Plug Conversion |

+1/+1 (see *3) |

+1/+1 (see *3) |

+1/+1 (see *3) |

+4/+5 | +1/+1 (see *3) |

+4/+5 | +4/+5 |

|

Downpipe 45mm with |

+2/+3 | +2/+3 | +2/+3 | +2/+3 | +2/+3 | +2/+3 | +2/+3 |

|

Open Collector |

- | - | - | 3/+1 | +3/+1 | +3/+1 | +3/+1 |

*1 Only in connection with 92 mm bore, oil cooler and combustion chamber work

*2 Only in connection with combustion chamber work; camshaft for sport use

*3 Is less of a tuning measure, it provides quieter engine running, better emissions

*4 Makes particular sense with conversion kit for 88 mm bore (851 cc) without crankshaft modification

The Details:

1. Valve Drive

Thanks to the rather “old fashioned” approach to the valve drive in 2-valve Guzzis we get the chance to improve a lot of things, not only as far as performance is concerned, but also running characteristics and lifespan. The common view that the original valve drive is meant to last forever is, unfortunately, not true. Pitting due to poor surface treatment and a lack of lubrication, or burnt outlet valves including seat rings prove the contrary. (The latter is due to the valve gap slowly opening up.)

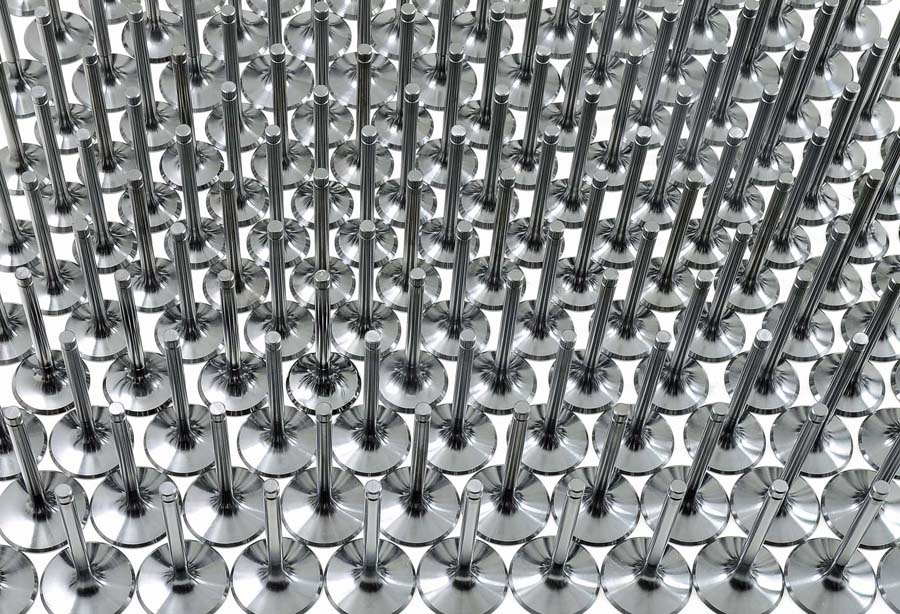

At the heart of any performance enhancement lies one of our five Valve Drive Kits, which one depends on engine type and requirements. A kit consists of an exchange camshaft, 4 valve springs and 4 valve spring collars, all made in Germany.

The cam followers do not have to be replaced unless they show wear or pitting.

Kit D-8.1:

Torque camshaft for significantly more power at low and medium revs as well as up to 9 PS increase for the models Le Mans 1-3 und all touring models with fuel injection or 36 mm carburettors. It is also a simple method of getting rid of the torque weakness in models with small bore cylinders, such as V7-Sport, 750-S, 750-S3, V7-Special.

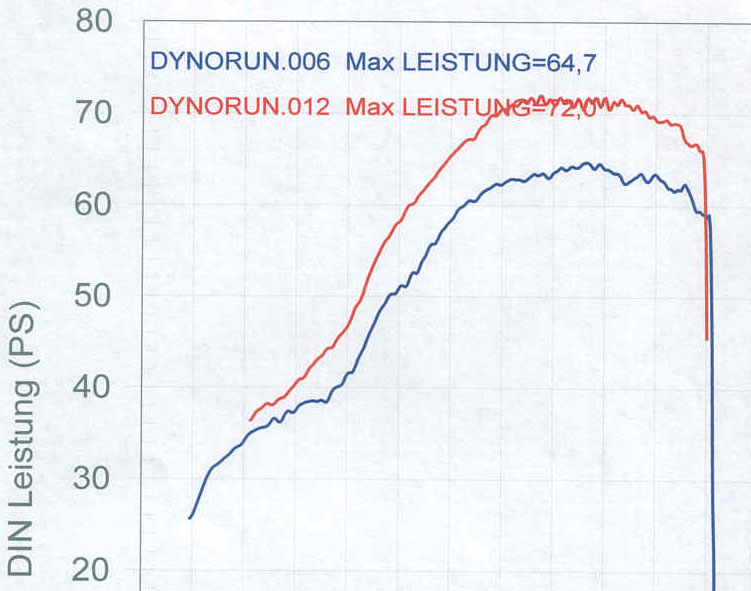

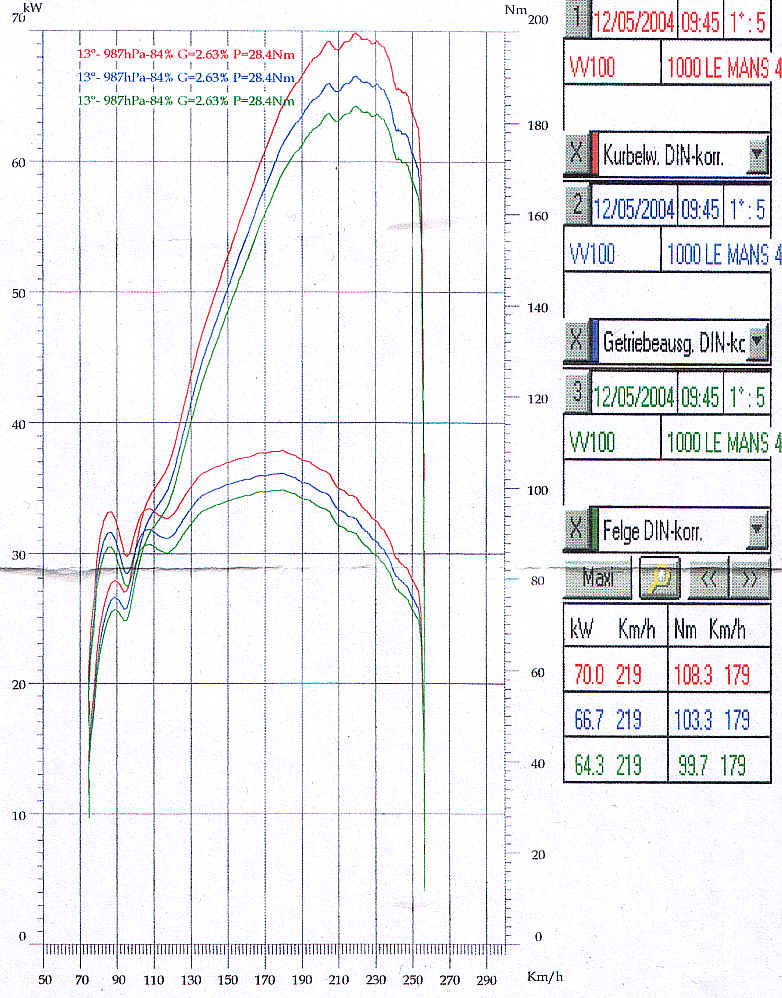

Diagram for Kit D-8.1 in California 1100, Spezial, Jackal, Stone, EV

Kit K-7.7

Camshaft for all touring models with 30 mm carburettors. Makes the engine more agile at all revs and pulls away more powerfully from the very bottom right up to top speed. It also works very well with those quiet production exhausts!

Kit D-7.2

Special torque camshaft for the models LM4/LM-1000. It removes the torque gap at medium revs.

Kit L-7.9

Performance camshaft for the LM1-LM3, 1100 Sport and LM4/1000 with a 92 mm bore as well as for the

V11 Sport, but some piston work is necessary!

Diagram for Kit L-7.9 in Le Mans 1000 with 92mm bore

Quality Issues:

Our camshafts are ground and plasma-nitrate coated in Germany, so despite the increase in performance, the life span of our valve drive is longer than that of the original. The lubrication holes ensure pressure oil lubrication between lobe and follower. This is another clear advantage over the original, where the holes are located next to (!) the cam lobes.

Here the comparison: the original camshaft is on the left, HMB D-8.1 on the right.

The valves open without hammering and the valve drive remains mechanically quiet and suffers very little wear. In order to accommodate the slightly ball-shaped form of the cam follower, the lobes are ground slightly asymmetrically. This keeps the surface pressure on lobes and follower low and prevents pitting.

Carefully selected valve spring kits matching the respective camshaft complete the Kit. Each spring is individually measured to keep tolerances low and to accommodate the engine type in question. The steel valve spring collars prevent damage to the collets and ensure a consistent spring distance. Each spring kit is marked with its own distancing requirements. (Please state engine type.)

Due to the valves quicker opening and their ability to rotate, burning of the valves and seats can be effectively prevented. As the thermal stress is now reduced, using unleaded fuel is no problem and doesn’t require any further changes. You can even use 91 octane petrol for some engine types.

After installing a Valve Drive Kit, the engine becomes more homogenous, economical and above all agile, and if you consider that the layout of the crankshaft, bearings, gearbox and end drive has not changed in the current engines producing up to 92 PS, it becomes clear that an engine optimisation makes sense for older Guzzis, especially when it’s without decreasing their life span. The riding fun definitely does not have to depend on the year of manufacture!

Coated valves:

Carbon coating makes these valves extremely hard, combined with a very smooth surface. This ensures low friction and wear between the valve stem and the valve guide resulting in a significantly higher lifespan. Thermal capacity is higher than of the originals, making these valves ideal for every high performance guzzi engine. Valve rotation, which is self evident for our valve drive kits, also benefits from low friction between the valve stem and the rest of the components. Deposit build ups are avoided or minimized by the smooth surface.

2. Bore Increase for Models up to 844 ccm

Particularly for the 850 cc models, increasing the bore to 88 mm – as is standard for the 1000 SP, Cali-2, LM-4 etc – would be worthwhile. The cylinders are Nigusil coated and experience shows that they last more than 100,000 km.

Although the old cylinders of the V7, 750-S, S3, 850-T, T3 were chrome-plated, the chrome layer gradually came off and caused damage to the entire engine. But the conversion to Nigusil coated cylinders makes sense for models with a standard 948 cc as well. The models 1000 SP, V1000 - G5 and V1000 Convert had cylinders with imprinted steel barrels which were worn after only a few thousand kilometres. Heat conduction, too, is inferior in these cylinders. We supply the cylinders for the 850 cc round finned engines ready to be installed, so the engine block does not require boring. And with a reasonable amount of extra work, the bore of V7 models with 750 cc can be increased as well. With a shortened 88 mm cylinder set, the cubic capacity is 851 cc, whilst keeping the original crankshaft. However, a few parts need modifying to achieve this. Please contact us for details.

In Italy, these cylinders are rated in several quality grades. We exclusively supply first grade cylinder sets. But still, every set is measured here individually before it goes into dispatch or stock.

Clearly visible, the old chrome coating im completely worn

Aber auch bei Modellen mit serienmäßigen 948 ccm kann die Umrüstung auf Nigusilbeschichtete Zylinder sinnvoll sein. Die Modelle 1000 SP, V1000 - G5 , V1000 Convert hatten Zylinder mit eingepressten Stahllaufbuchsen, die nach wenigen tausend Kilometern schon verschlissen waren. Auch die Wärmeableitung ist bei diesen Zylindern schlechter. Auch für die 850 er Rundmotoren liefern wir die Zylinder einbaufertig, das auf spindeln des Motorblocks entfällt. Den V7 Modellen mit 750 ccm können wir mit vertretbarem Mehraufwand zu mehr Hubraum verhelfen. Mit einem gekürzten 88mm Zylindersatz beträgt der Hubraum 851 ccm unter beibehaltung der Originalkurbelwelle. Natürlich müssen dazu noch einige Teile modifiziert werden, bitte kontaktieren Sie uns für nähere Informationen. In Italien werden diese Zylinder in mehreren Qualitätsstufen angeboten, bei uns bekommen Sie immer 1. Wahl. Das stellen wir mit einer Eingangsprüfung sicher, in dem wir jeden Zylindersatz auf Laufspiel und Ovalität vermessen.

3. Bore Increase for Models up to 948 ccm

We can supply coated cylinder sets with a bore of 92 mm (1038 cc) for square finned engines starting from the Le Mans 3. For the newer California and V11 models, we offer cylinder sets with a bore of 95 mm.

These cylinders are tailor-made for each engine type and ensure a significantly higher torque from the 1134 cc capacity. The cylinder material (including Mahle pistons) is made in Germany and guarantees maximum operating safety. Performance increases in the range of 10 PS and 10 Nm are possible, depending on the model – even higher when using one of our Valve Drive Kits. Due to the changed mass ratio, balancing the crankshaft is essential, as is work to the combustion chamber. For an engine performance over 100 PS, we recommend Carrillo con-rods due to their better stability. Feel free to call us if you require advice.

4. Reworking the Combustion Chamber

To optimise the squish-band, we have to shorten the cylinders. This is the only way to ensure a thorough mixture of fuel and air. We then measure the volumes of the combustion chambers to achieve the correct compression ratio, balanced for both cylinders. This also compensates for tolerance differences in the components and ensures that the engine runs more quietly. It also reduces emissions and enhances fuel consumption. In the sport engines with a bore of 92 mm (1100 Sport, V11 Sport) the squish-band is machined at an angle for emission reasons, but this leads to a noticeable torque loss at medium revs. Here, we can compensate for a lot by reworking the combustion chamber. Depending on camshaft type, the combustion chamber is reworked with regard to valve play and the valve pockets. If larger carburettors are used, the inlet channels are reworked accordingly. If desired, the cylinder heads can be converted to twin plugs. This is especially recommended for big bores and high piston domes and has a beneficial effect again on fuel consumption and emissions.

5. Making square finned engines round.

In fact, this does not look like a tuning measure. But if we take a closer look, it is...

The square finned engines from LM-3, Cali-2 do not only have more fin surface for cooling, the studs are also further apart which allows bores up to 92 mm without any further modifications of the housing., including a rocker arm base made of aluminium. Valve sizes up to 47/40 mm were standard, while the round engines had a maximum of 44/37 mm. Of course, we can build a unique round finned engine with bigger bore and valves, but the effort and cost is quite high. And we are far off from using stock parts, making exchange more difficult in case a spare part is needed.

So why not make a sqare engine round. We machine the fins of cylinders and heads to a round shape, almost like the old round engins were. But only almost, as we want to preserve a maximum of coolig fin surface. We did not want to copy the round engine, we wanted a more steadfast engine, using as many stock parts as possible, combined with a unique classic style. We supply cnc made adaptors to fit the old round valve covers, either V7 or T3 style covers will complete the modification. Performance is of course excellent, if someone fits a modified V11 engine into his T3, he will experience the difference of the original 50 to then 90 horsepower, including according torque... Steadfast !

Of course carb setup, Ignition etc. must be adapted to these modifications. As usual, Hmb-Moto will supply a plug and play solution, or even a complete ready to ride bike. Ask us!

|

|

|

|

6. Twin Plug Conversion

A twin plug conversion is less of a tuning measure, but rather an optimisation. The long spark travel in the combustion chamber requires high initial ignition values, which in turn carries a risk of self-ignition (ringing). By igniting the mixture from two sides, the chances of pre-ignition can be reduced considerably. Combustion becomes more even and effective, starting behaviour and torque are enhanced. Twin plugs generally make sense for large bores and high piston domes.

We use 10 mm spark plugs and a special stay bolt. This way, the seat of the rear stay bolt does not require reducing so there is no danger of the cylinder head distorting. The conversion kit contains the special stay bolts, spark plugs and spark plug spanner. We change the ignition advance characteristics (depending on the engine type) regardless of whether the vehicle is fitted with an interrupt ignition or an electronic ignition system.

7. Carb Setup

We will balance the optimised engines on the dynom and on road using a lambda test device. Test bed measurements alone are useless (although offered again and again) as they do not factor in the airflow. Only on the road can realistic conditions be achieved. Starting with jet sizes drawn from past experience, we conduct several measuring rides until the best possible setup has been found. Only then are we in possession of all the relevant factors (incl. intake and exhaust system) to ensure the mixture is exactly right.

For commom engine configurations like: "850 LM-1, 88er Bore, Camshaft HMB D-8.1, open Lafranconi exhaust", there is no need for another dyno run.

We can then supply a plug and play carb setup ! Please ask us.

8. Decreasing Mass

As the production clutch on the pre-1993 models is very heavy, decreasing the centrifugal mass is another possibility. We decrease the weight of the flywheel and the starter ring gear and balance the components. After an initial decreasing, the flywheel weighs only 1.65 kg, the ring gear 1.35 kg. The reaction of the engine improves, whilst the gearbox is protected. The production clutch with newer fine-tooth clutch boss has proved steadfast in tuned engines with over 100 PS as well, which cannot be said of many single-disc clutches on the market...

Therefore, we believe that decreasing the centrifugal mass of the original clutch is a sensible and inexpensive alternative.